Can`t buy a jtagualator then build it - DIY build under 75USD

Published on Nov 2, 2024 by IoTSRG Team

Hello, everyone! Welcome to this blog where we delve into the motivation and process of building a JTAGulator, an invaluable tool for test engineers, developers, and hackers alike. If you’re looking to identify on-chip debugging interfaces such as JTAG, UART, or SWD, this blog is for you!

Note: This Price mentioned under india imported and custom taxes together, we ordered in bulk

Motivation and Introduction to JTAGulator

The idea for this blog came when we realized how challenging it was to source a JTAGulator within India. JTAGulator, an open-source tool by Joey Grand from Grand Idea Studio, is essential for identifying various interfaces on embedded devices. JTAGulator supports multiple debugging protocols, including:

- JTAG

- UART

- SWD

- GPIO logic analysis

The tool lets you configure aspects like input-output voltage, making it versatile. Despite being launched at DEFCON 21 back in 2013, it remains popular due to its reliability. Given its rarity in stock, we decided to take matters into our own hands and build one!

Starting the Build: The PCB

Our first step was downloading the Gerber file from Grand Idea Studio’s website link to the gerber file below . As per the Creative Commons Attribution 3.0 Licence, full credit goes to Joey Grand and Grand Idea Studio. We then uploaded this Gerber file to a local PCB manufacturer, which cost us approximately 350 INR (4.5 USD) per PCB.

Download: here

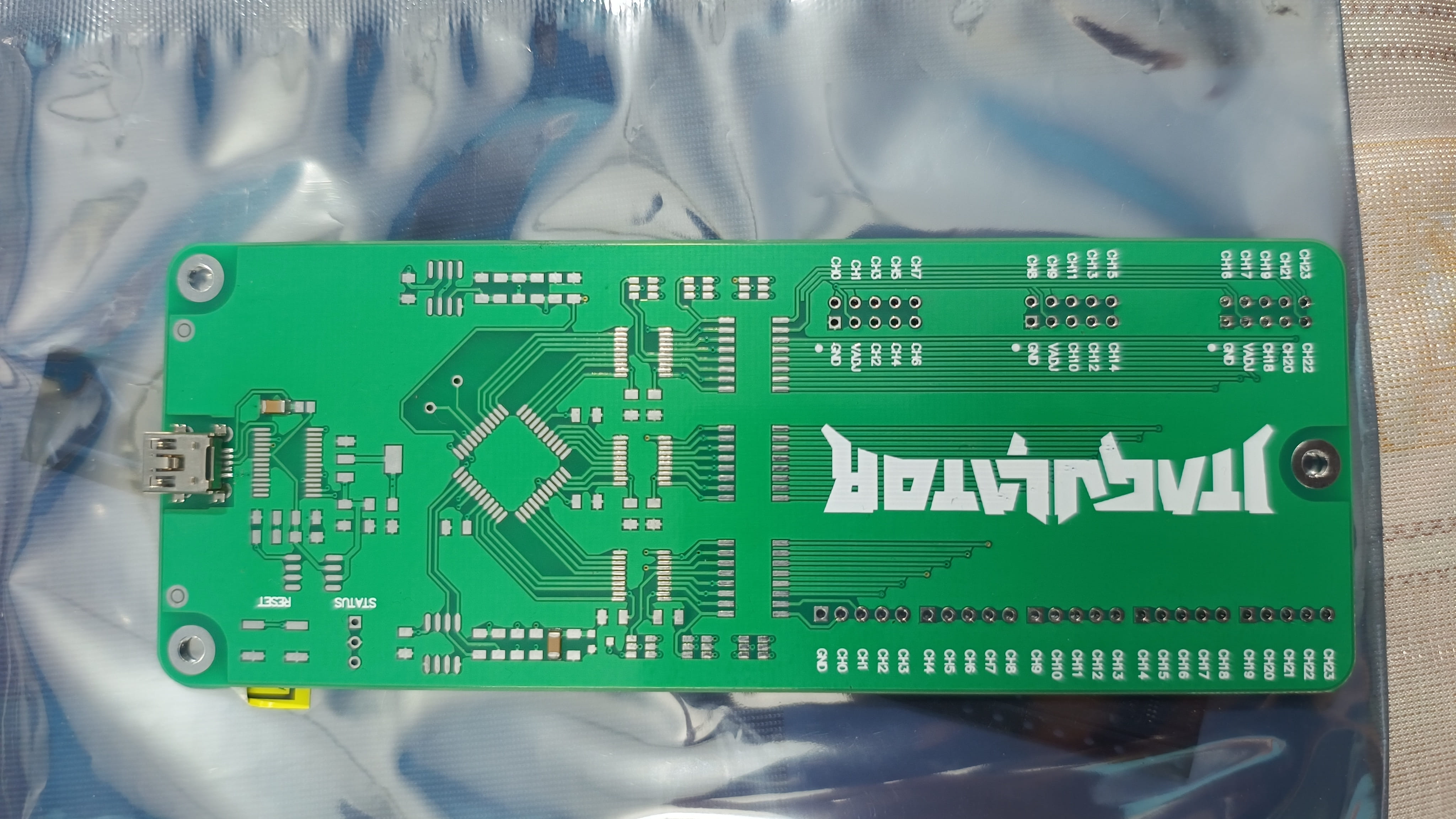

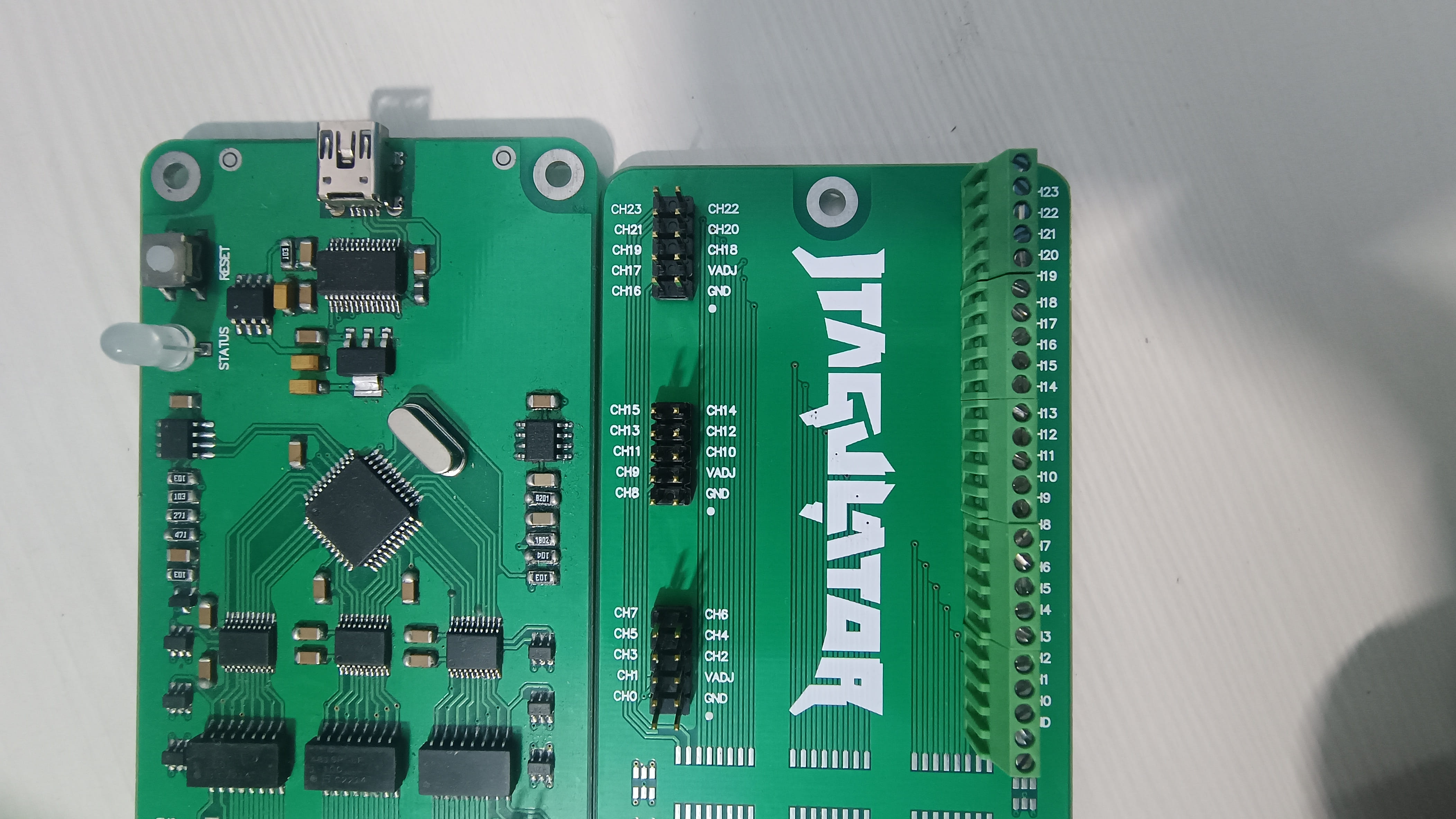

JTAGulator PCB layout .

Gathering Components: Bill of Materials (BOM)

The BOM, available on Grand Idea Studio’s website, provides essential details:

- Quantity

- Reference (e.g., C for capacitor, D for diode)

- Manufacturer and Part Number

- Distributor (e.g., DigiKey)

Keep in mind that some countries have specific import regulations for electronic components, so preparing for customs clearance is essential.

BOM.

Assembly and Soldering

With the PCB and components ready, we began assembling the JTAGulator. Here’s a list of tools and materials we used:

- Solder Paste (Mechanic brand)

- Brush and Blade Set

- Soldering Station and BGA Rework Station

- Tweezers and PCB Holder

- Stereo Microscope for precision soldering

- Multimeter for continuity and voltage tests

Assembling.

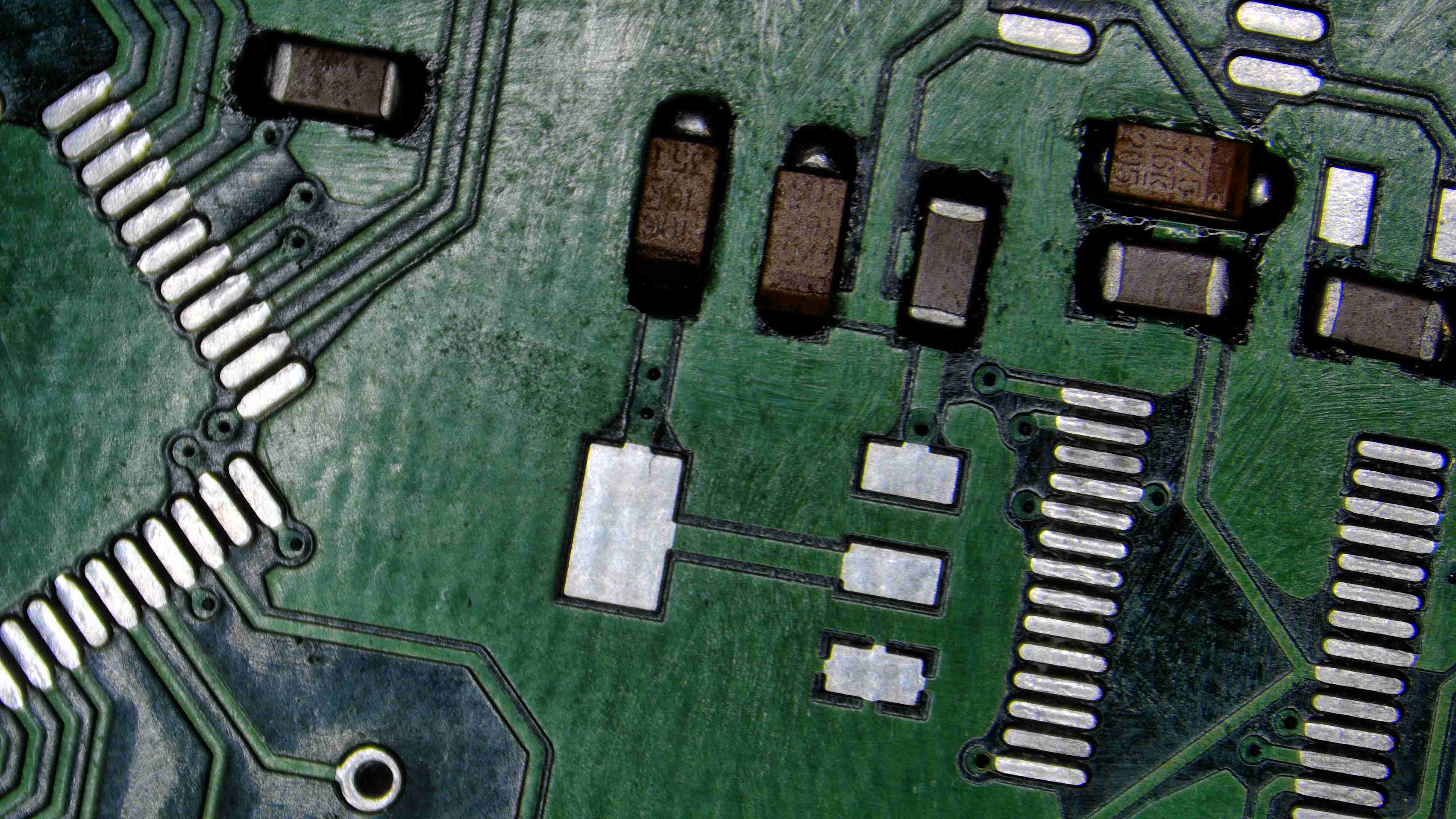

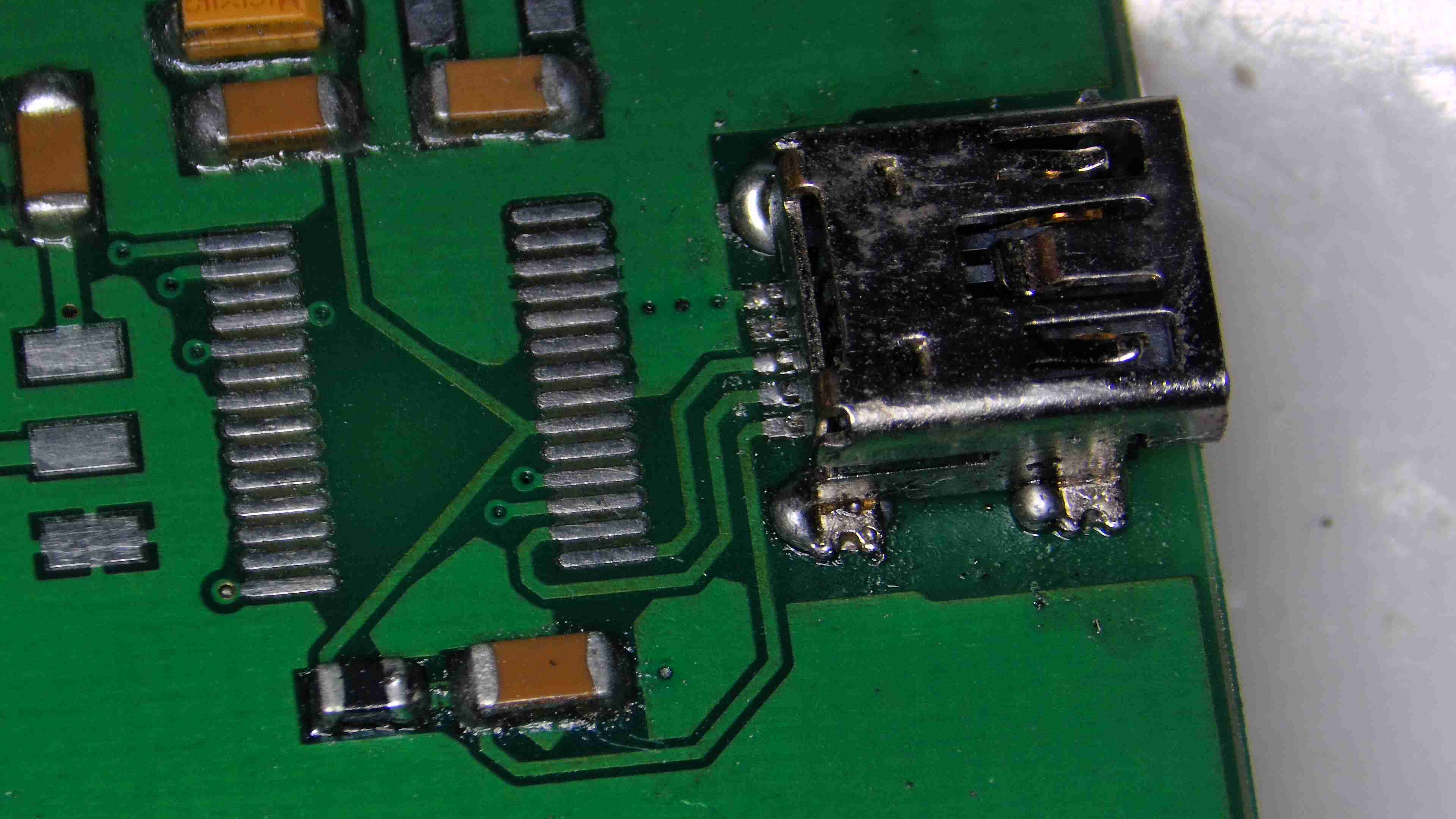

The assembly process was straightforward but required careful placement of each SMD component, especially those with polarity, like tantalum capacitors. Capacitors, resistors, diodes, and ICs were placed according to the BOM.

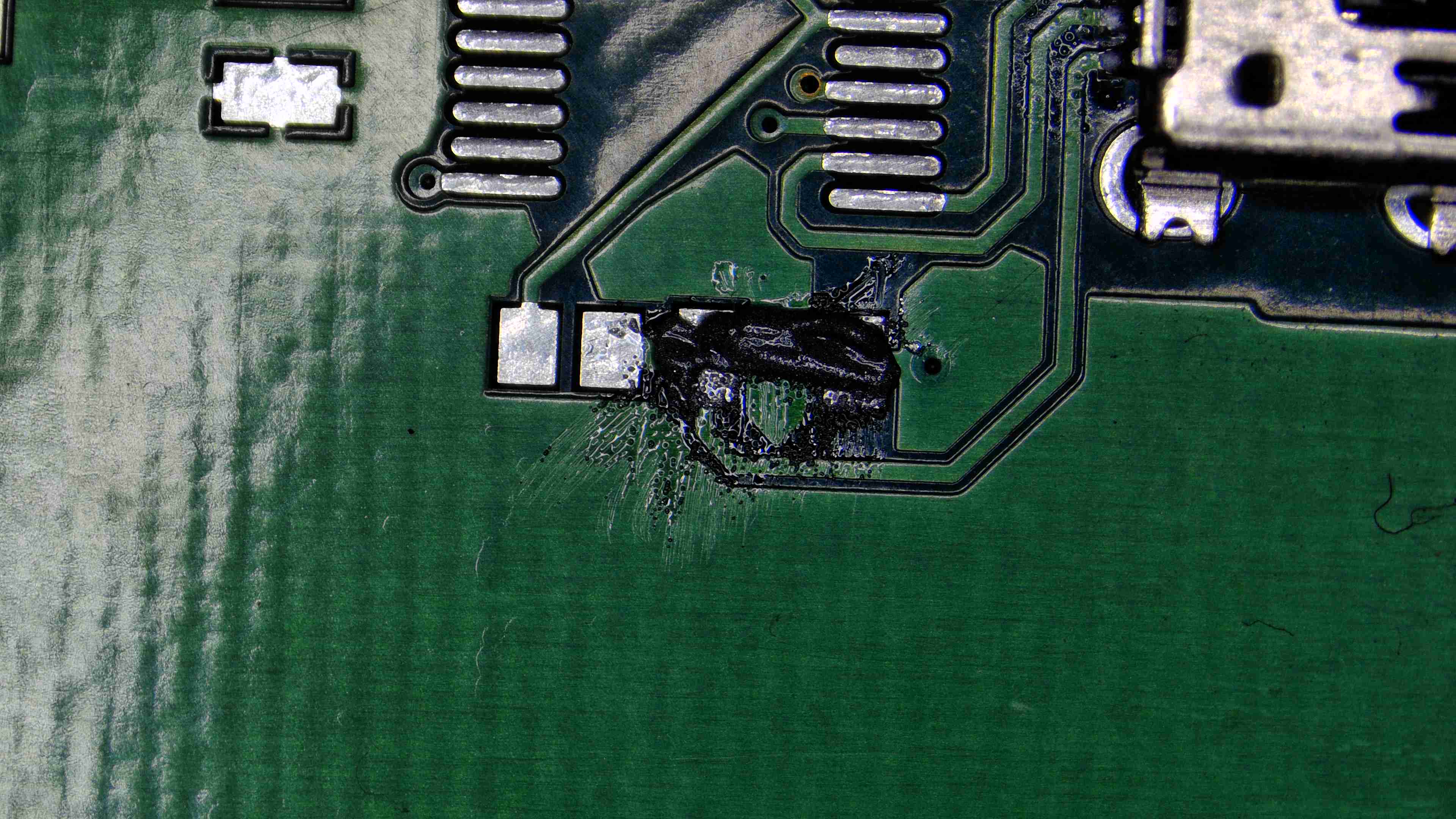

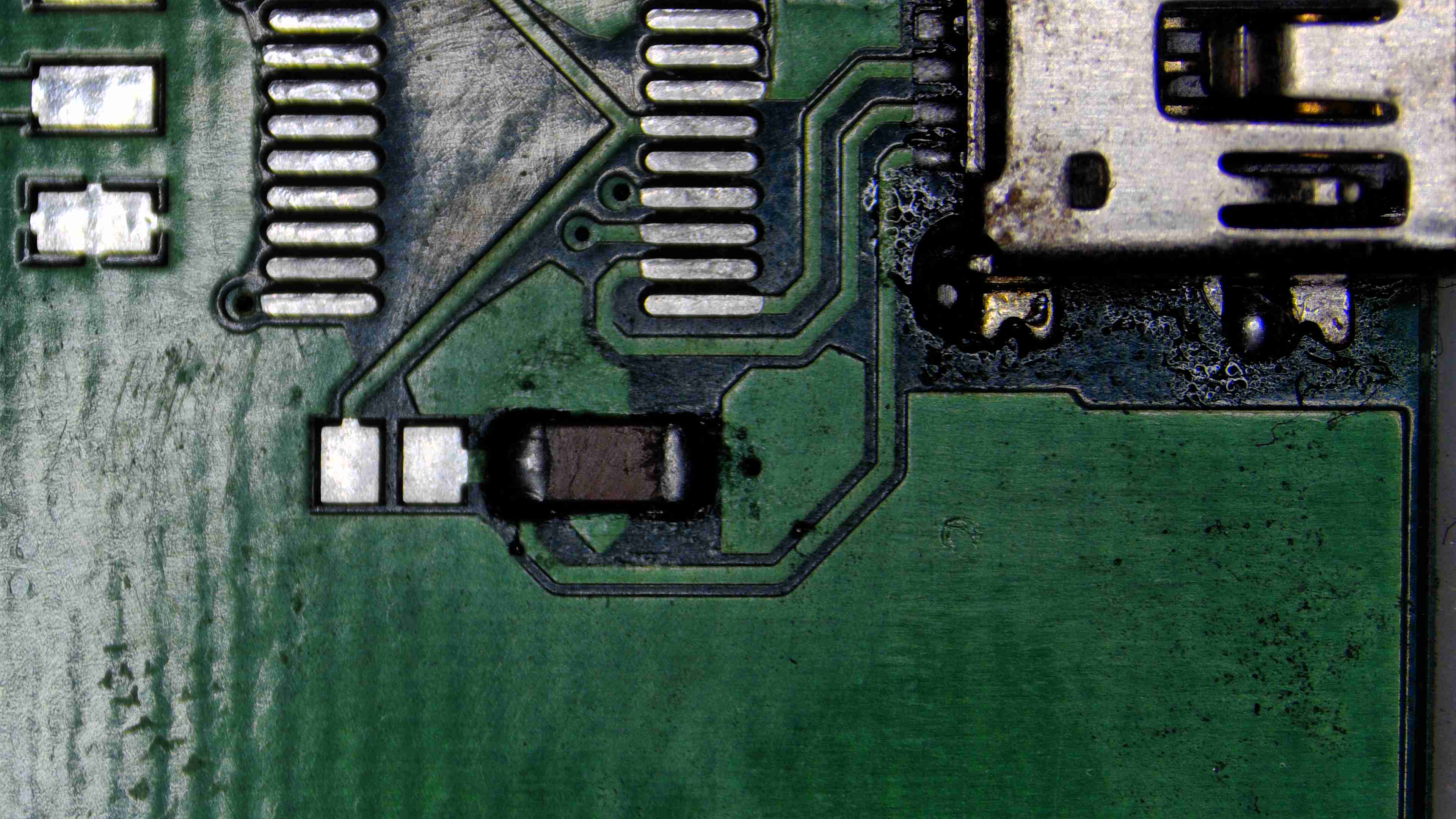

Soldering Steps and Troubleshooting

Following the component placements, we checked for shorts using a multimeter. When soldering, be mindful of potential shorts, especially with small SMD components. Isopropyl Alcohol was used to clean up excess flux.

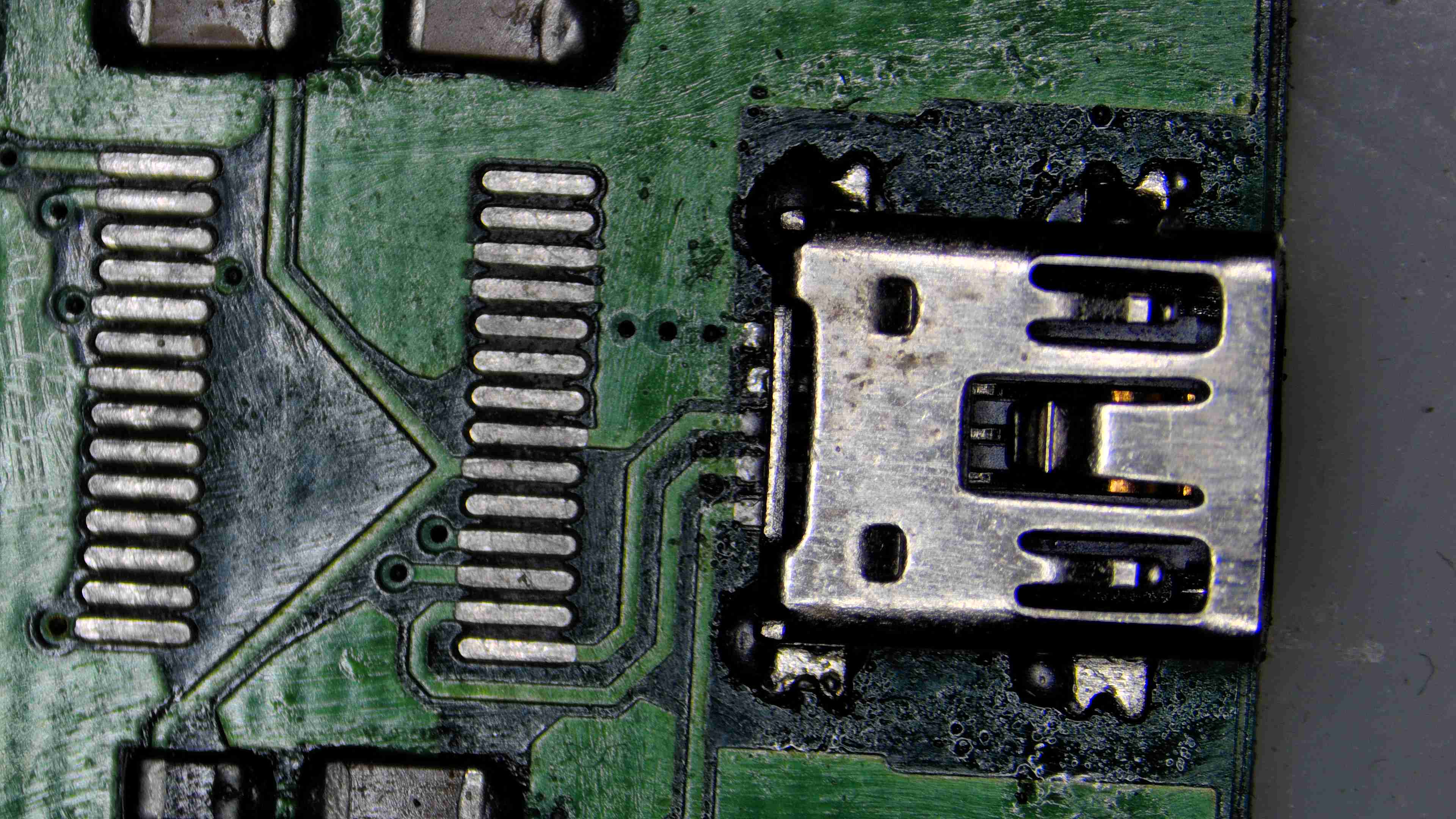

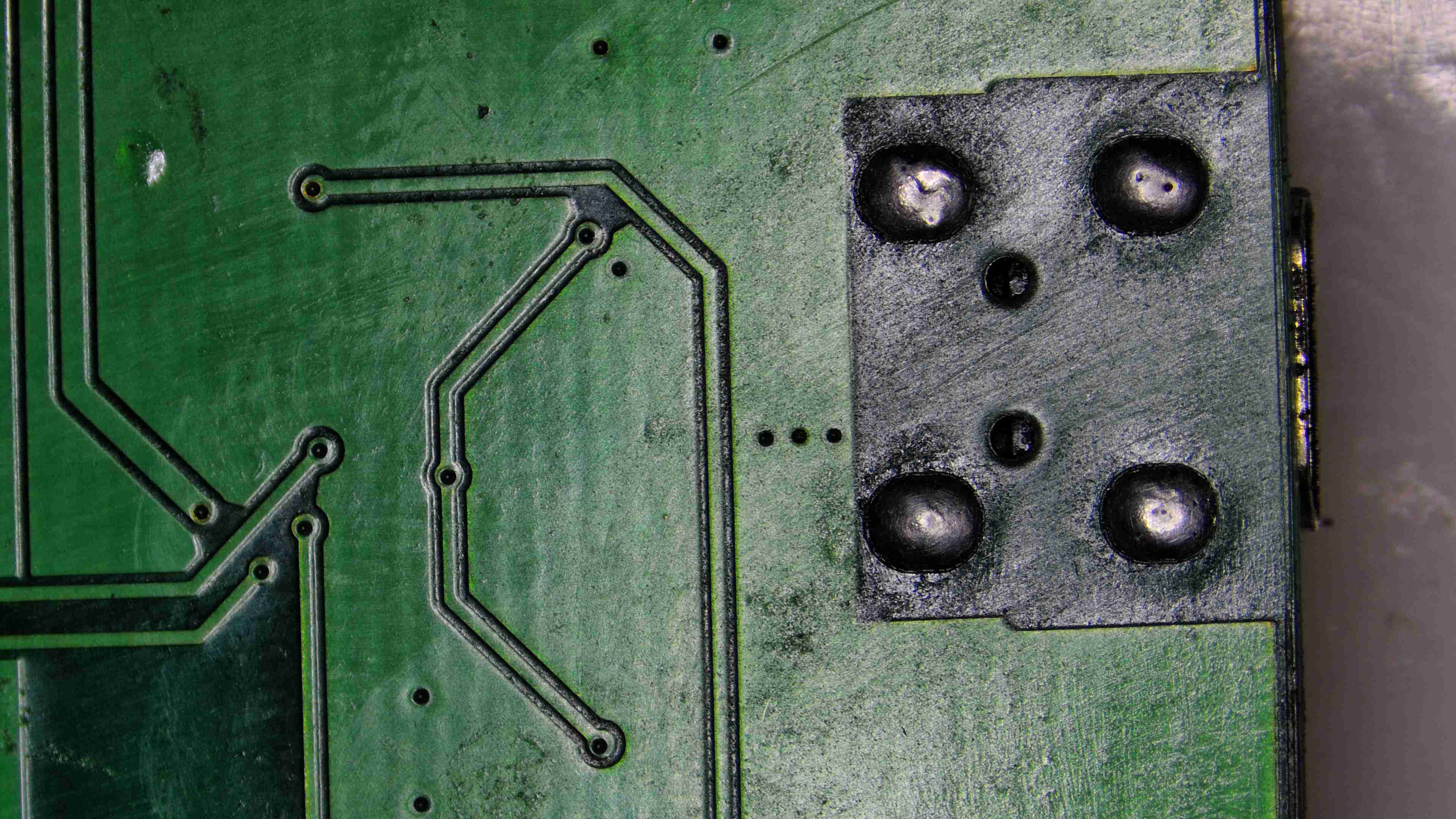

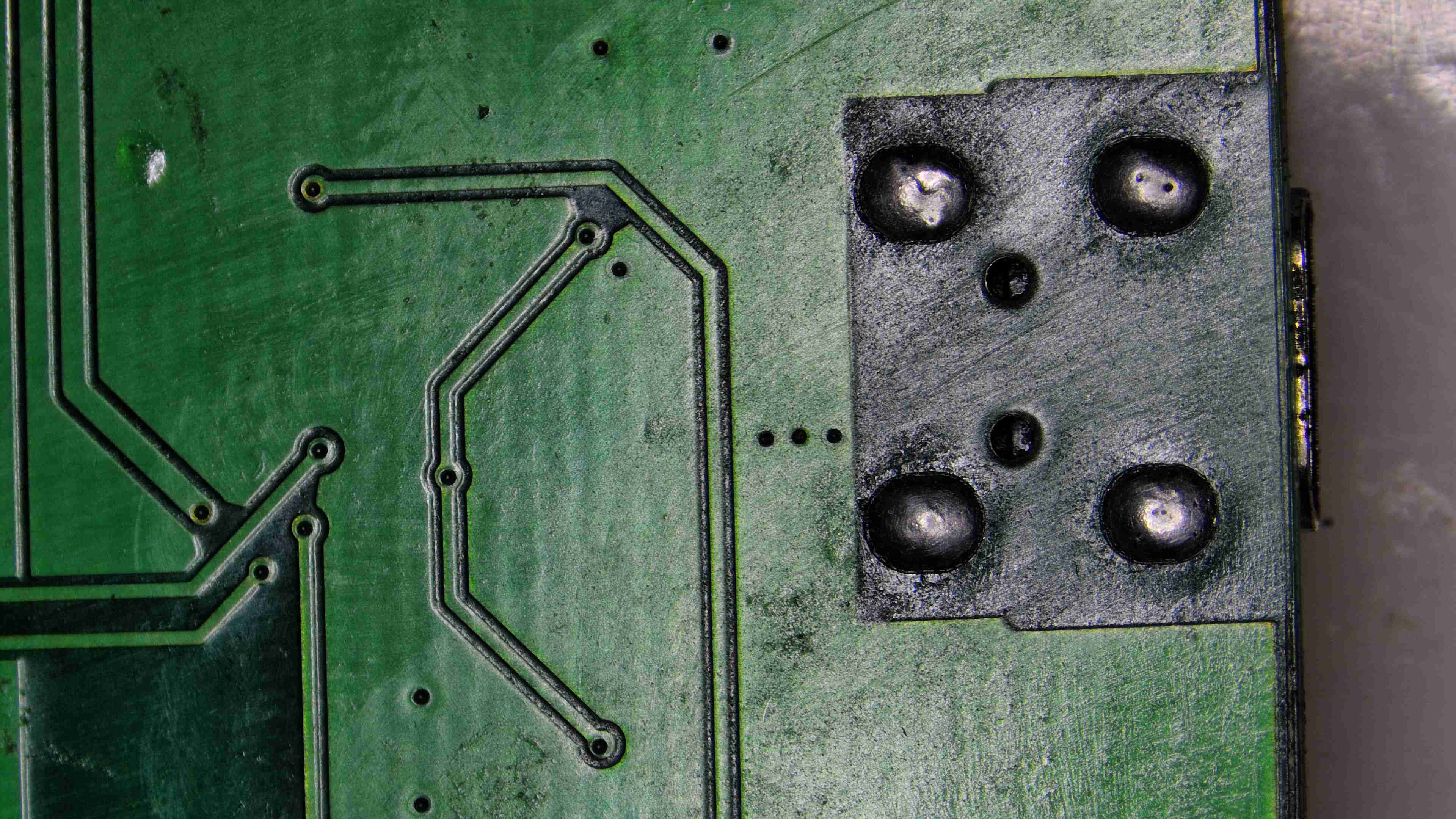

Picture of capacitor and IC placements with the cleaned board.

Final Assembly and Testing

After completing the soldering, we followed the test procedure(https://grandideastudio.com/media/jtagulator_testproc.pdf ) from Grand Idea Studio’s website, ensuring all connections were stable. We also checked that the JTAGulator’s USB port was recognized by our system.

If the USB port isn’t detected, it usually indicates a short somewhere on the PCB mostly on the IC’s. Once connected, we flashed the firmware using Parallax Propeller

Powering Up and Validation

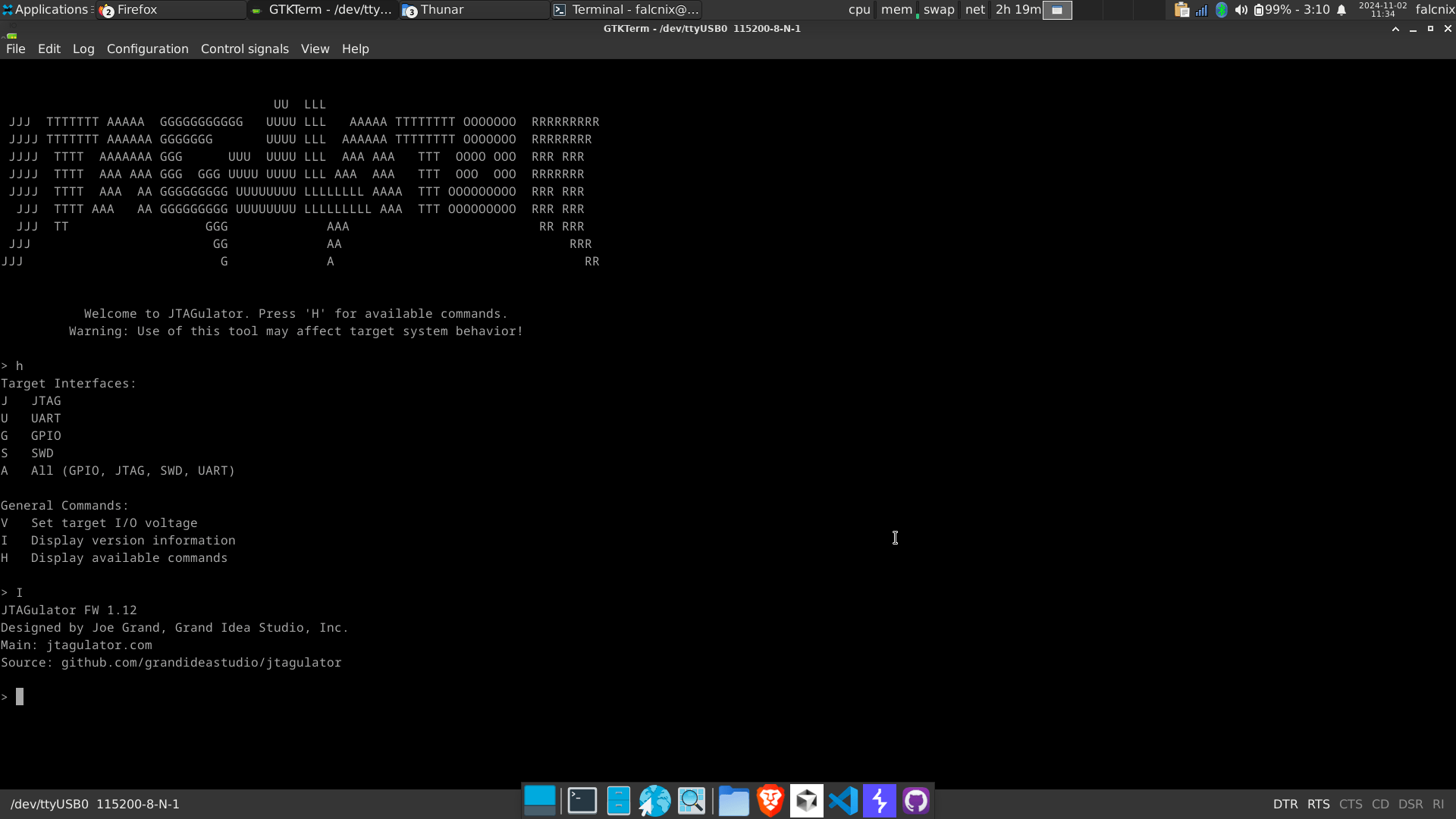

After successfully flashing the firmware, we connected the JTAGulator via a serial console (e.g., GTK term) with a baud rate of 115200. When done correctly, the device will display the JTAGulator page and light up in green.

Picture of JTAGulator with green LED.

Tool(https://grandideastudio.com/media/P8X32A-Setup-Propeller-Tool-v1.3.2.zip ) (specific version provided in JTAGulator’s GitHub repo).

Successfully working.

And there you have it! With patience and precision, building a JTAGulator can be both rewarding and cost-effective. Stay tuned for more detailed guides and happy hacking!

Final Cost Estimate

Building a JTAGulator yourself, including the PCB and components, costs approximately 5500 INR (around 66 USD). This DIY approach not only saves on expenses but also gives you hands-on experience in assembling and configuring a powerful debugging tool.

Happy Learning! 🎉 Embrace the hacker’s way bruteforcing pins and hacking them