Microprobing with ICEBite - A Definitive Guide for Solderless Testing Probes

Published on Jul 14, 2024 by IoTSecurity101 Team

Inspired by the renowned PCBite and Pizzabite from the WHID team, we are proud to unveil ICE-Bite, an affordable, open-hardware solution tailored for the Indian market. ICE-Bite is engineered to provide a cost-effective and user-friendly option for securely holding PCBs during soldering or inspection. This innovative tool ensures precision and convenience without the need for soldering, making it an essential addition to any technician’s toolkit.

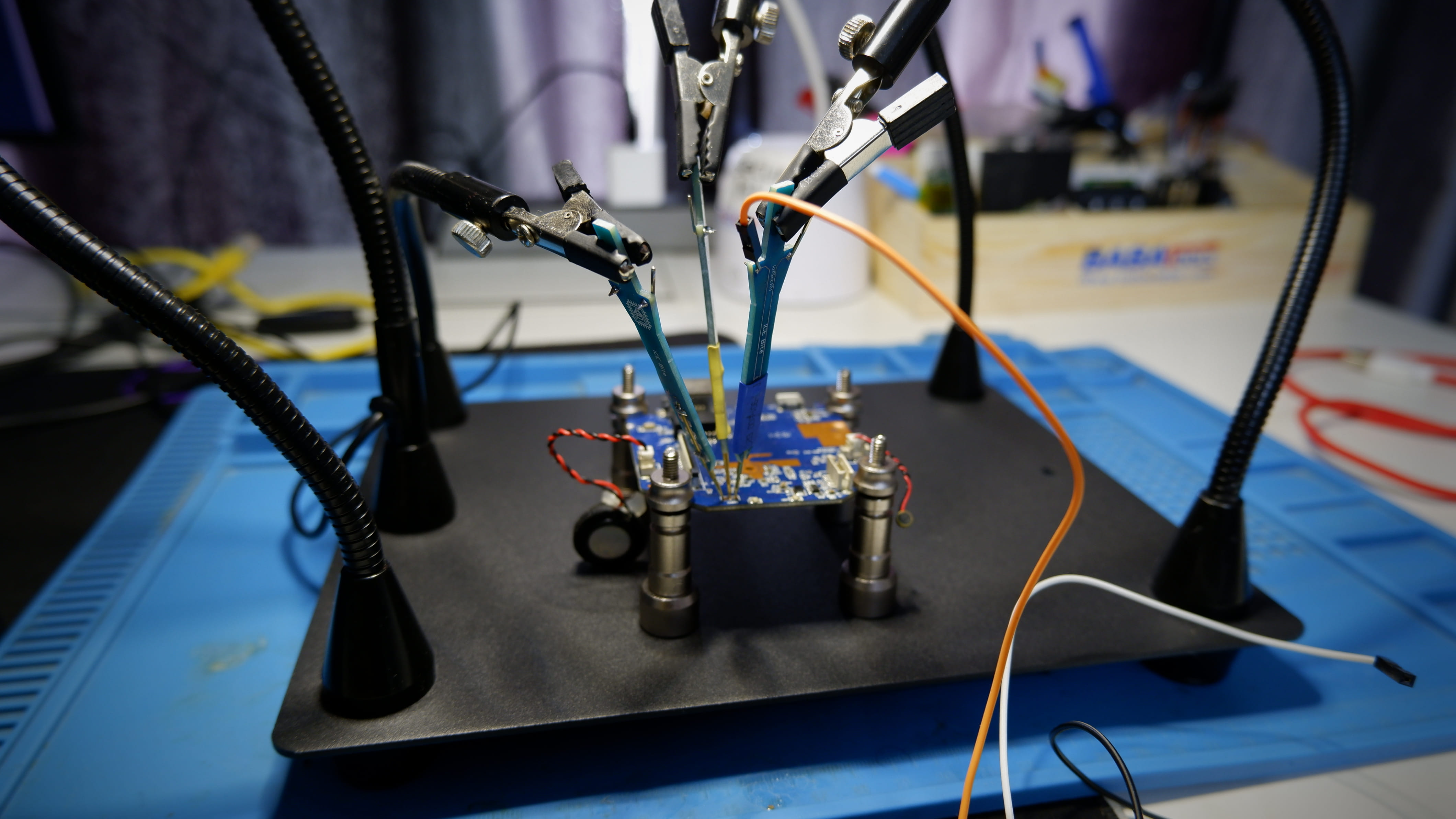

Gives us vibes of Dr.Octopus…

Requirements:

1. Spring Pogopins:

s Diameter of 1.36 or 1.38 mm for making secure connections with 3A and 5A supports, usually these pins are expensive. Depending on requirements, we can change. For cost-effectiveness, we are using P100-B1 Dia 1.36 mm 180 g.Alternative:

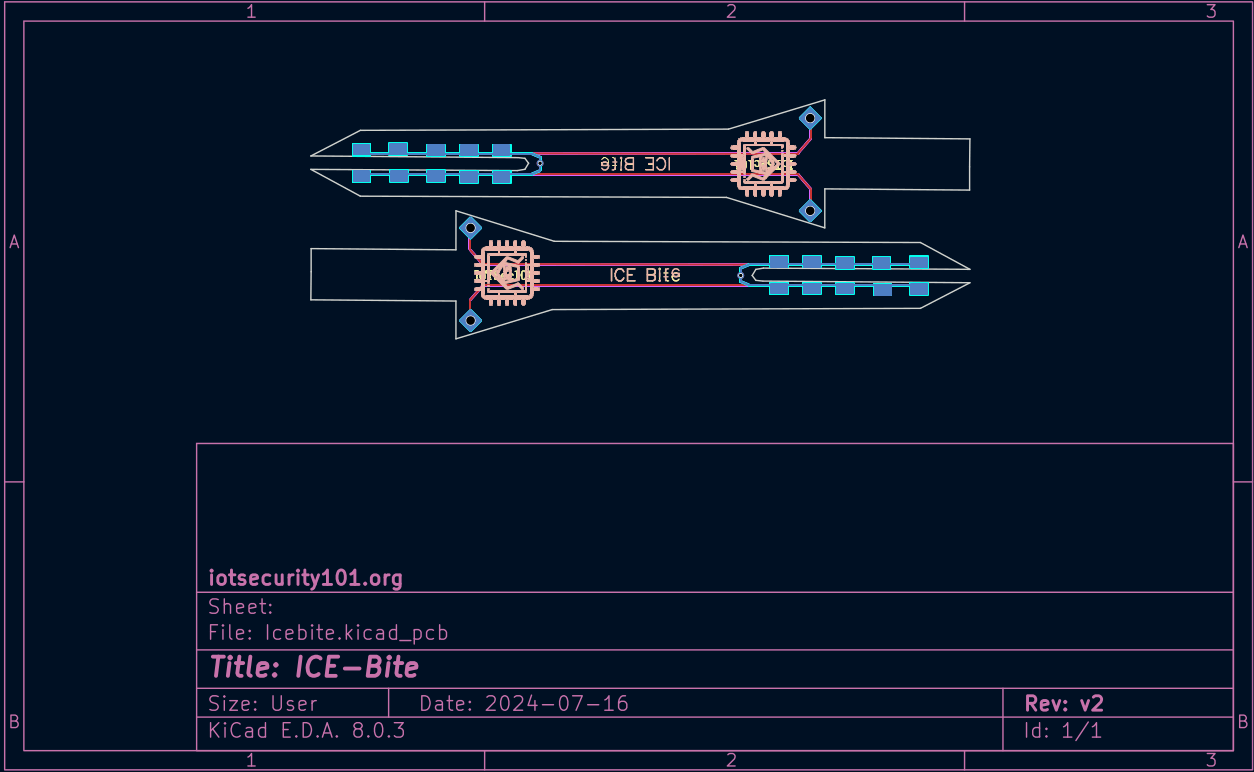

2. PCB Design:

Custom-designed PCB specific to ICE-Bite.

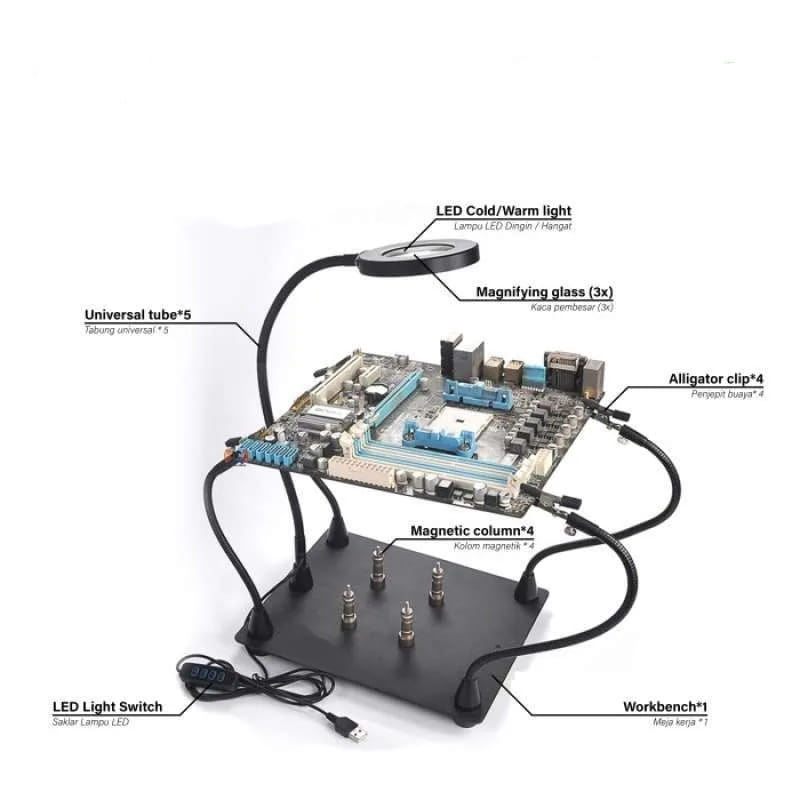

3. Soldering Flexible or Helping Hands:

Provides a sturdy foundation, equipped with crocodile clamps for secure positioning. Tools to assist with holding components in place. Universal magnifier helping hand fixture table for motherboard PCB.

4. Target PCB Holder:

Ensures stability while working on the PCB.

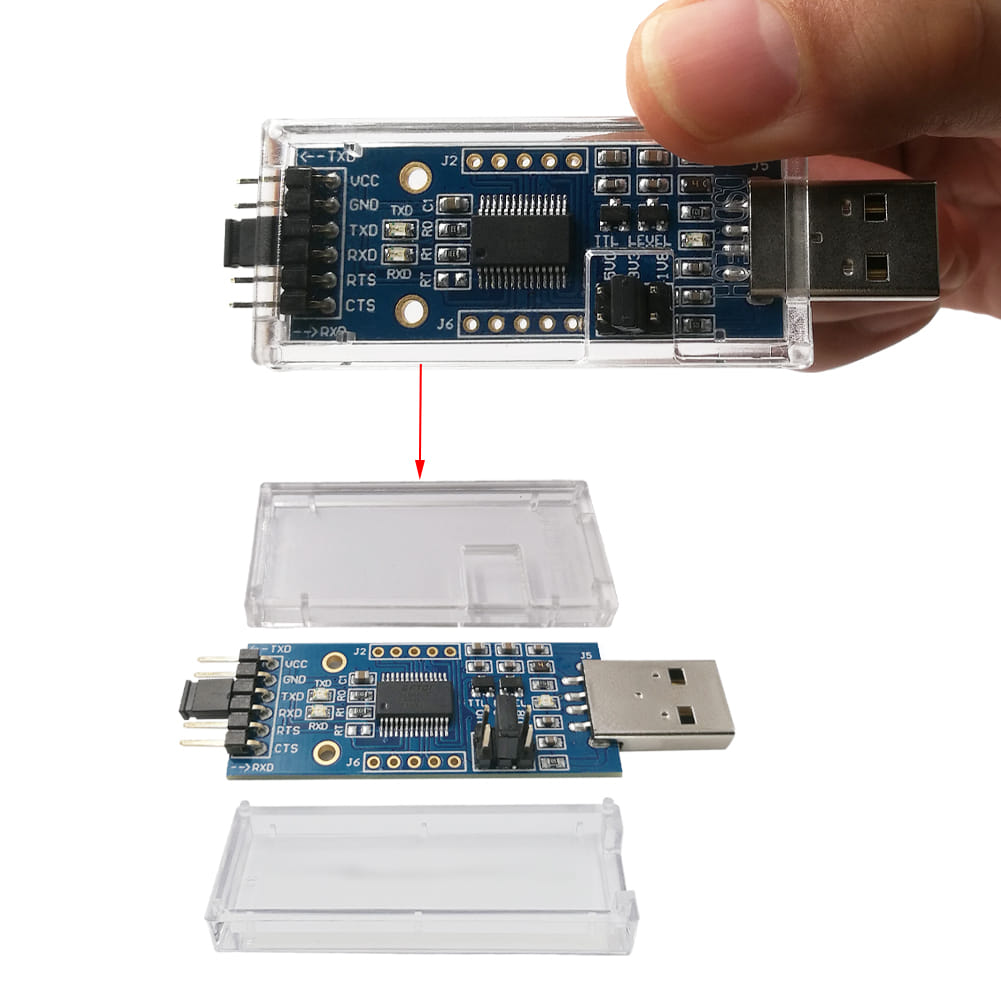

5. SH-U09C5 USB to TTL Adapter:

Microprobing with ICE-Bite:

Workspace Preparation:

- Ensure a clean, well-lit, and organized workspace. Gather all necessary ICE-Bite components and tools along with an ESD mat.

Assembling ICE-Bite:

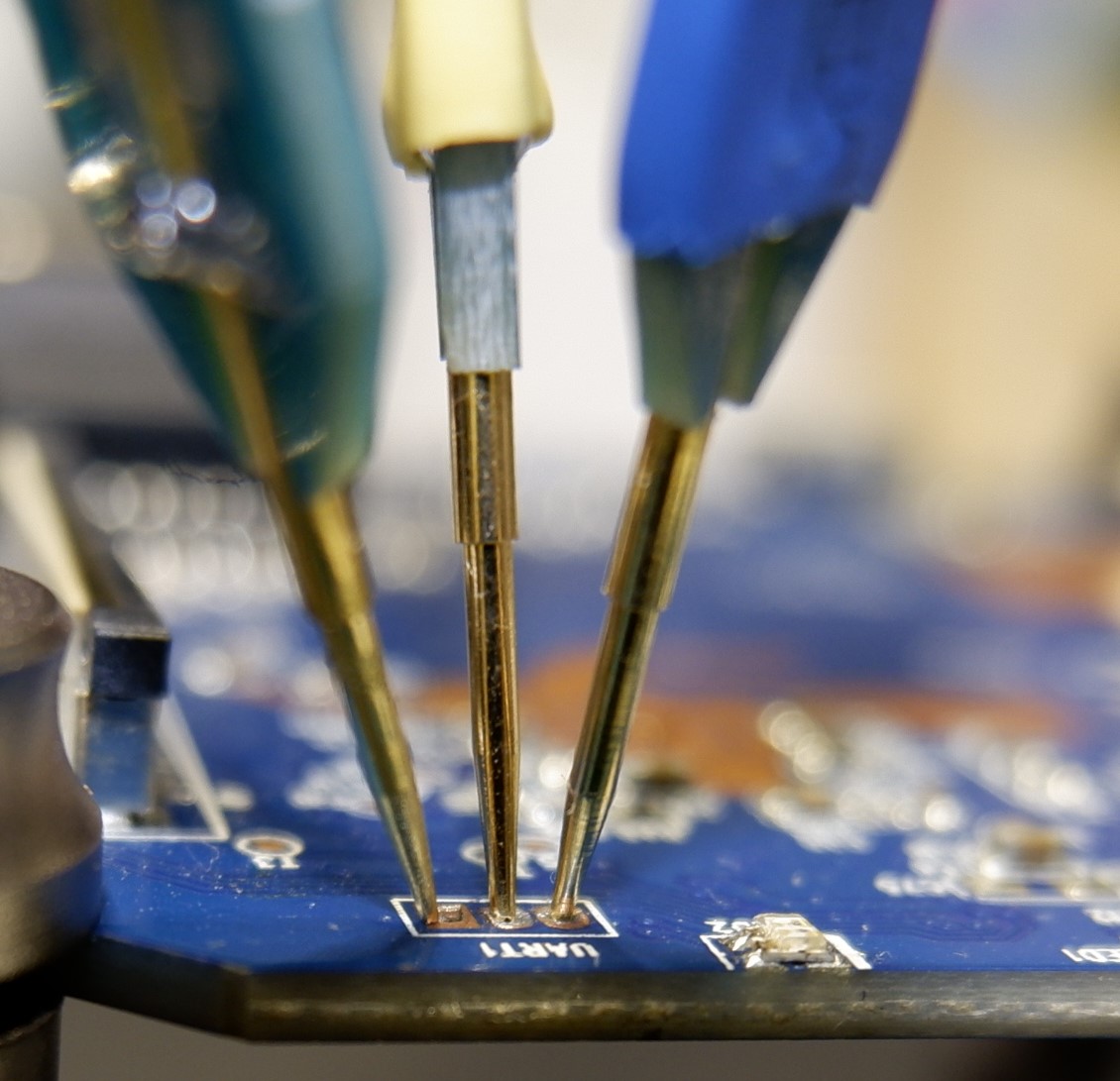

- Attach the spring pogopins to the designated slots on the PCB holder.

- Secure the PCB in the holder using the crocodile clamps for stability. Adjust the position as needed to ensure a firm hold.

Positioning the PCB:

- Place the PCB onto the holder, aligning it with the pogopins.

- Adjust the flexible arms and helping hands to firmly hold the PCB in place, ensuring all contact points are secure.

Conducting Testing and Inspection:

- Use the pogopins to make precise contact with the test points on the PCB.

- Perform your testing or inspection tasks, leveraging the stability and precision offered by ICE-Bite to avoid any damage to the PCB.

- Monitor the PCB for any signals or data as needed, taking advantage of the easy access provided by the solderless setup.

Video Tutorial:

Post-Use Procedure:

- Carefully remove the PCB from the holder to avoid damaging any components.

- Disassemble and clean ICE-Bite components as necessary.

- Store ICE-Bite and its components in a safe, organized manner for future use.

Key Benefits of ICE-Bite:

Precision and Stability:

Ensures secure and stable holding of PCBs, allowing for precise testing and inspection without the need for soldering.User-Friendly:

Designed for ease of use, making it accessible for both professionals and beginners.Cost-Effective:

Offers an affordable solution for PCB testing and inspection, particularly tailored for the Indian market.Happy Learning! 🎉 Embrace the hacker’s way of mastering PCB testing and inspection with ICE-Bite.